Last Updated on November 25, 2022 by mdmtool

There are many differences between stepper and DC motor. The main difference between a stepper motor and a DC motor is that the stepper motor can rotate in precise increments while the DC motor cannot. This makes stepper motors ideal for applications requiring specific positioning, such as 3D printers and CNC machines. DC motors are more suitable for applications where speed is more important than accuracy, such as electric vehicles.

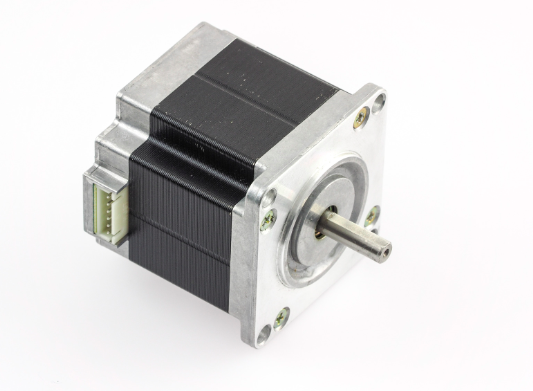

What Is A Stepper Motor?

A stepper motor is an electromechanical device that converts electrical pulses into discrete mechanical movements. The advantage of a stepper motor is that it can be controlled with high precision without needing feedback sensors.

There are two main types of stepper motors:

- Unipolar stepper motors have one winding per phase, while bipolar stepper motors have two windings per phase.

- Bipolar stepper motors are generally more efficient and have higher torque than unipolar stepper motors.

What Is A DC Motor?

A DC motor is an electric motor that runs on direct current (DC) electricity. DC motors are more versatile than stepper motors. DC motors are classified according to the type of excitation they use. The three most common types are

- Permanent magnet DC motors are the most common in consumer applications such as power tools and electric vehicles.

- Series wound DC motors, such as conveyor belts, are typically used in industrial applications where high starting torque is required.

- Shunt wound DC motors are more efficient than other DC motors and are usually used in applications where precision is essential, such as robotics.

Stepper Motor Vs. DC Motor

- Nature of loop: Stepper motors have a discrete number of steps, so the rotor turns in fixed increments. DC motors do not have this limitation and can rotate continuously.

- Speed Range: Stepper motors can be very slow or fast but are typically limited to low speeds. DC motors have a more comprehensive speed range and can operate at high speeds.

- Starting torque: Stepper motors have high starting torque, which means they can start from a standstill. DC motors typically have lower starting torque and may require a mechanical or electronic device to help them begin.

- Effect of overloading: Stepper motors can be overloaded without damaging the engine. DC motors, on the other hand, can be damaged if overloaded.

- Motor Control: Stepper motors can be controlled with a microcontroller or dedicated stepper motor controller. DC motors require a more complex motor controller, such as an H-bridge.

- Precision and Reliability: Stepper motors are more precise than DC motors and can be used for applications that require high accuracy. However, they are less reliable than DC motors and may require more maintenance.

- Torque: Stepper motors have high starting torque and can operate at high speeds. DC motors have a more comprehensive speed range and can provide continuous motion.

- The efficiency of the Motor: Stepper motors are more efficient than DC motors.

- Size of the Motor: Stepper motors are available in many sizes, from small to large. DC motors are also generally in a wide range of sizes but are typically larger than stepper motors.

- Noise Factor: Stepper motors are generally quieter than DC motors. T

- Fault Detection: Stepper motors are more likely to fail than DC motors. This is because the stepper motor can be controlled with a microcontroller or dedicated stepper motor controller, providing the necessary feedback. On the other hand, DC motors require an external feedback system, such as an encoder, to ensure accuracy.

- Durability: Stepper motors are more durable than DC motors.

- Consumer design: Stepper motors are more likely to be used in consumer products than DC motors.

- Performance: Stepper motors are more likely to perform better than DC motors.

Pros And Cons Of DC Motor

Pros:

- Little or no maintenance required.

- Very rugged and can operate in a wide range of environments.

- Can be easily controlled with a variety of methods, including mechanical, electrical, and electronic means.

- Can be configured to run at high speeds.

- High starting torque.

Cons:

- Not as efficient as other types of motors

- Can generate a lot of heat

- Can be noisy

- Requires more power to start than other types of motors

Stepper Motor Pros And Cons

Pros:

- Stepper motors can be exact, making them ideal for applications requiring high accuracy levels.

- They can also be used in open-loop control systems, which simplifies the design and implementation of the overall system.

- Stepper motors are available in a wide range of sizes and power ratings, making them suitable for various applications.

- They are relatively simple to control and can be easily interfaced with various electronic devices.

Cons:

- Stepper motors can generate a lot of heat, which can be a problem in some applications.

- They are also generally not as efficient as other types of motors and can require more power to operate.

- Stepper motors can be noisy and vibrate when operating at high speeds.

- They also tend to be less reliable than other motors and may require more maintenance.

FAQs

How do we compare a stepper motor driver and a stepper motor converter?

When it comes to controlling a stepper motor, there are two main types of devices: a stepper motor driver and a stepper motor controller. Both of these devices serve the same purpose; to convert a DC power supply into the correct type of current for driving a stepper motor.

Can the position of DC motors be controlled precisely?

No, because the back EMF of a DC motor changes as its speed changes, which affects the torque that the motor produces.

What is a commutator in a DC machine?

A commutator is a rotating switch that reverses the current direction in a DC machine. It consists of a set of copper bars connected to the armature windings and mounted on the DC machine’s shaft.

What is the difference between a stepper and a servo motor?

The main difference between a stepper and a servo motor is the type of feedback control loop that each uses. A servo motor uses a feedback control loop to ensure the rotor is positioned correctly, while a stepper motor does not.

Conclusion

When choosing between a stepper motor and a DC motor, it is essential to consider the application and the desired level of precision. Stepper motors are more precise than DC motors, making them ideal for applications that require precise positioning. However, they are also more expensive and require more complex control circuitry. DC motors are less expensive and easier to control but are not as precise. Ultimately, the decision between a stepper motor and a DC motor depends on the specific application and the required level of precision.