Last Updated on November 9, 2022 by mdmtool

In electrical engineering, contactors and relays are two main types of switching devices. A typical contractor can handle currents up to several thousand amperes and is used to control AC circuits. In comparison, a standard relay can only manage a few hundred amperes and is used to control DC circuits.

Both devices serve the same purpose of controlling an electric circuit by opening or closing the circuit, but there are some critical differences between the two.

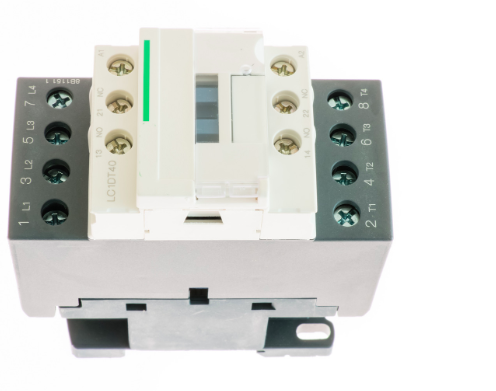

What Is A Contactor?

A contactor is an electrical device used for switching an electrical circuit on or off. It is controlled by a switch or timer and can handle large amounts of current.

What Is A Relay?

A relay is an electrical device that switches an electrical circuit on or off. It is controlled by a switch or timer and can handle small amounts of current.

Comparison Between Contactors And Relays

Working Principle: The contactor attracts the other electromagnet and closes the contacts; when the control electromagnet is energized. This completes the circuit and current flows.

While in relay when the control electromagnet is energized, it attracts the armature and closes the contacts. This completes the circuit and current flows.

Current Handling Capacity: A contactor can handle large currents, up to several thousand amperes, while a relay can only handle small amounts of current, typically a few hundred amperes.

Structure: Contactor has two electromagnets. One is used to control the other. Relay has only one electromagnet.

Load Capacity: Contactor can handle large loads such as motors, lights, etc. Relay can handle small loads such as lamps, fans, etc.

Control Circuit: In contactor the control circuit is separate from the primary circuit, while the control circuit is part of the primary circuit in relay.

Size: Contactor is more prominent in size due to the two electromagnets. Relay is smaller in size as it has only one electromagnet.

System Voltage: Contactor can be used in both low and high-voltage systems. Relay is used in low-voltage systems only.

Power Consumption: Contactor consumes more power than relay as it has two electromagnets while relay has only one electromagnet.

Open/Closed Contact Standards: The contact must be open when the coil is de-energized in contactor. In relay the contacts can be opened or closed when the coil is de-energized.

Auxiliary Contacts: Contactor has one or more pairs of auxiliary contacts while relay does not have any auxiliary contacts.

Control: Both are controlled by switches or timers.

Voltage: Contactor can be used in both low and high-voltage systems, while relay is used in low voltage systems only.

Enclosures: Contactor is available in several different enclosures, while relay is only available in a few enclosures.

Poles And Throws: Contactor has two poles and one throw. Relay has one pole and one throw.

Mechanical Interlock: Contactor has a mechanical interlock. Relay does not have a mechanical interlock.

Dielectric Strength: Contactor has a high dielectric strength than relay.

Insulation Resistance: Contactor has a high insulation resistance than relay.

Switching Speed: Contactor has a high switching speed. Relay has a low switching speed.

Suitability For Inductive Loads: Contactor is suitable for inductive loads. A relay is unsuitable for inductive loads because it has a higher contact resistance.

Cost: A contactor is more expensive than a relay.

Applications: Contactor is used in air conditioners, refrigerators, pumps, motors, etc. Relay is used in computers, telephones, automobiles, etc.

FAQs

How Do Contactors And Relays Work?

Both contactors and relays use an electromagnet to operate a switch mechanically. When the electromagnet is energized, it creates a magnetic field that moves the switch to the “on” position. When the power is removed from the electromagnet, the button returns to the “off” position.

What Are The Types Of Relays?

- Electromechanical relays (EMRs)

- Solid state relays (SSRs)

- Reed relays

- Latching relays

- Time delay relays (TDRs)

- DIP & SIP, PCB mount

- Automotive relay

What Are The Types Of Contractors?

- Auxiliary contacts

- Power contacts

- Contact Springs

Conclusion

Picking a suitable device for your application is important to ensure safe and reliable operation. Both contactors and relays are widely used in industrial and commercial applications. Be sure to consult an expert if you are unsure which device suits you.